The production is directed mainly to the sectors:

AUTOMOTIVE – BICYCLE AND MOTORCYCLE – TECHNOLOGY – SECURITY

INTERIOR DESIGN – LIGHTING – APPLIENCES – BOATING

In the production site at Santa Maria di Sala (Venice – Italy), on a covered surface of 2500 square meters and 3000 square meters outdoor and independent, the company has:

⇓

|

|

In the production site at Turin (Italy) on a covered surface of 2000 square meters, the company has:

⇓

|

|

Our main work phases:

- Decal application

- Washing

- Sanding

- Painting

- Smoothing

- Polishing

- Quality inspection

- Cleaning

Test:

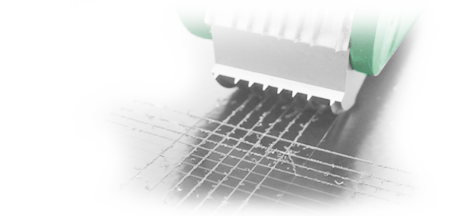

Moreover, the company uses electronic equipment for the measurement of gloss (certified gloss meter) and technical equipment for the gripping test (cross hatching). It makes use of external laboratories for additional testing on customer specification.